EpoxyGuard® Epoxy Floor Paint Coating Kit Advantages

EpoxyGuard® is a 100% solids epoxy coating that bonds mechanically to a surface to create an impervious barrier that will guard your floor from damage caused by salt, fluids, chemicals and automobile wear and tear. Unlike other epoxy concrete floor paints, EpoxyGuard® is not water or solvent based, which means that when you apply our coating there is no product shrinkage due to evaporation. Using a 100% solids epoxy coating will ensure long lasting adhesion and wearability. EpoxyGuard® epoxy paint can be applied effectively to a variety of surfaces.

Our business is to protect concrete flooring from contamination and wear and tear with our industrial grade epoxy floor coating system.

EpoxyGuard's methods of concrete floor protection, using 100% solids resin-based “floor paint”, have been a proven standard in the industrial floor market for all concrete floor coating needs from heavy manufacturing, commercial, institutional, and now also as a residential floor coating system for use on garage floors, wood floors and metal surfaces.

Floor Paint & Floor Coatings - A Technical Analysis for Concrete Floor Protection.

Since the inception of epoxy resin in 1936 by Dr. Pierre Castan of Switzerland and Dr. S.O. Greenlee of the United States, there have been thousands of combinations of epoxy formulations for many different industries. Here are some of the leading industries that currently use epoxy: floor paints and coatings, adhesives, industrial tooling and composites, electrical systems and electronics, consumer and marine applications, aerospace applications, art, wind and energy applications. This article will focus on the floor paint and coating industry and what the best product is for its application.

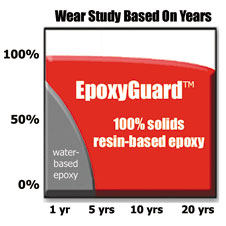

Although there are many choices one can make when deciding which type of epoxy to apply, one must understand that there is a clear and definite technical hierarchy. Below is a chart that ranks epoxy for effectiveness.

EPOXY TECHNICAL HIERARCHY

| #1 | 100% Solids Resin-Based Epoxy | 10 to 20 mils Dry Film Thickness (D.F.T.) | No solvents/no V.O.C. | 2 component with a 2 to 1 mix ratio. |

| #2 | Solvent-Based Epoxy | High Build 2 to 4 mils Dry Film Thickness (D.F.T.) | 40 to 55% volume solids with 45 to 60% Solvents with Shrinkage and Evaporation. | 2 component with a 1 to 1 mix ratio. |

| #3 | Solvent-Based Epoxy | Low Build 1 to 2 Dry Film Thickness (D.F.T.) | 30 to 40% volume solids with 60 to 70% Solvents with Shrinkage and Evaporation. | 2 component with a 1 to 1 mix ratio. |

| #4 | Water-Based Epoxy | 1 to 1.5 mils Dry Film Thickness (D.F.T.) | 30 to 40% volume with 60 to 70% Shrinkage and Evaporation. | 2 component with a 1 to 1 mix ratio and/or 1 component. |

| #5 | Waterborne Epoxy | Same as #4 | Same as #4 | Same as #4 |

| #6 | Modified Epoxy Sealer | 1 to 2 mils Dry Film Thickness (D.F.T.) | 5% Epoxy additive with approx. 30% of other active ingredients and fillers. 30 to 40% volume with 60 to 70% Shrinkage and Evaporation. | 1 component moisture cured product. |

| #7 | Oil-Based Acrylic Enamel (Porch and Deck Paint) | 1 to 1.5 mils Dry Film Thickness (D.F.T.) | 30 to 40% volume with 60 to 70% Solvents Shrinkage and Evaporation. | 1 component moisture cured product. |

| #8 | Moisture cured Polyurethane Sealers | Same as #6 | Same as #6 | 1 component moisture cured product. |

| #9 | Acid Stains | No mil rating of thickness | Penetrating Sealer with concrete to chemical color reaction properties upon contact. | 1 component moisture cured product. |

| #10 | Water-Based Stain | No mil rating of thickness | Penetrating water based stain sealer. | 1 component moisture cured product. |

| #11 | Standard Sealers: Applications for concrete patios, sidewalks, driveways, brick pavers and stampings. | NA | NA | 1 component |

ADVANTAGES:

100% solids epoxy (resin-based industrial grade) epoxy floor paint is far superior to all other concrete floor paints, floor sealers and floor stains available today. 100% solids epoxy was developed as a high performance protective floor coating to protect concrete floor surfaces from high volume traffic of hilos (tires/steel forks) and constant wear and tear to concrete floor substrates. Along with wear and tear to concrete floor surfaces, mechanical machines and equipment also leak oils and fluids. Without proper concrete floor protection, such as the recommended 100% solids epoxy, these oils and fluids will be absorbed through the concrete and into the soil beneath, resulting in contamination and potential deterioration to the floor surface. Consequently, these oils and fluids in the soil can potentially lead to future environmental concerns.

Concrete surfaces are very porous and soft compared to the 100% solids epoxy floor paint. That being said, imagine the concrete surface acting as a big sponge that holds and retains water, fluids, dirt, oil, grease, dust, mold and other substances that absorb into a porous surface. Unprotected concrete floor surfaces will yield a decreased life span. 100% solids epoxy is a permanent solution to the problems listed above.

The following are other very important advantages in using 100% solids epoxy floor paint:

- Surface restoration and repair

- Increased light reflectivity

- Resists hot tire marks

- Chemical resistant

- Abrasion resistant

- Industrial grade

- Easy to clean

- Slip resistant

- Salt resistant

- Oil resistant

- Self leveling

- High gloss

- Aesthetics

CONCRETE SURFACE PREPARATION:

Concrete floor surface preparation for new or old concrete floor surfaces must be clean, contaminant-free and profiled/etched for proper bonding/adhesion of 100% solids epoxy floor paint.

NEW CONCRETE FLOORS:

Contaminant-free concrete floors must be mechanically surface profiled with either a diamond grinder, shot blaster or chemically etched with a recommended 4 to 1 part ratio acid-based or inorganic acid concrete cleaner and etcher.

OLD CONCRETE FLOORS:

(1). Oil soaked, dirty, greasy, spawled, or cracked concrete floors must be degreased and cleaned with a heavy concentrated degreaser followed by a rinse bath. Repeat until satisfied.

(2). Fill all cracks with recommended cementatious crack filler and/or any non-silicone based epoxy, polyurethane joint sealant that is paintable.

(3). Profile the surface with the recommended mechanical method or chemical etch method.

100% solids resin-based industrial grade epoxy is the only choice for concrete floor protection to paint your garage, shop, and basement or for any other indoor concrete floor surface.

See below: List of all other products available for concrete floors in today’s market, starting with the best product at the top of the list, which is 100% solids epoxy, followed by the rating of performance levels from wear and tear to mil thickness and chemical resistance.

EPOXYGUARD 2-PART EPOXY PRODUCT DESCRIPTION:

TECHNICAL:

The EpoxyGuard Floor Paint Coating Kit is a two-component epoxy resin, containing no solvents or coal tar. EpoxyGuard epoxy resin is designed for use in both interior and exterior (if top coated) applications.

BASIC USES:

EpoxyGuard is recommended for several basic applications:

-

As a base resin used as a coating, to encapsulate wear resistant aggregates and as a lock coat.

-

As an overlay with aggregate, to provide traction and wear resistance to concrete floors. Filled with silica sand, aluminum oxide or other suitable wear resistant filler.

LIMITATIONS:

- EpoxyGuard should be installed above 55° F.

PACKAGING:

-

Available in 1.5-Gallon, 3-Gallon, and 7.5-Gallon units

-

STANDARD COLORS

- Light Gray

- Dark Gray

- Tan

INSTALLATION:

Shot blasting must be employed to provide a clean concrete floor substrate. In areas where shot blasting is not feasible, utilize other methods of surface preparation such as concrete acid etching/cleaning.

Apply the EpoxyGuard resin to a dry surface.

COATING SYSTEM:

Parts A and B should be mixed separately before combining. When combined, mix thoroughly with a low speed motor and included mixing wand, always scrape the container's sides and mixer blades. Do not aerate the mixture.

Mixing ratio: 2 parts A to 1 part B by volume.

|

Property |

Test Method |

Test Results |

|---|---|---|

|

Weight per Gallon |

10.1 lbs/gal. |

|

|

Hardness (Shore D) |

ASTM D2240 |

70-80 |

|

Viscosity @ 77°F (24°C) |

ASTM D2196 |

2000-5000 cps |

|

Cure Time @ 75°F (24°C) |

ASTM C920 |

12-24 hours |

|

Abrasion Resistance |

ASTM D4060 Tabor 1000 rev CS17 Wheel, 1000 g |

Loss 0.08 grams |

|

Weathering Resistance |

ASTM G53-83 |

Yellowing |

|

Tensile Strength |

ASTM D412 |

7300 psi |

|

Ultimate Elongation |

ASTM D412 |

15.00% |

|

Tear Resistance |

ASTM D1004 |

180 pli |

|

% Yield |

99.00% |

|

|

Shelf Life @ 77°F (25°C) |

(Over 1 year in sealed containers) |

|

|

Chemical Resistance |

Unaffected by gasoline, oils, and coolants. |

CONCRETE OVERLAY:

Use as a slurry coat to add strength and wear resistance. Mix Parts A & B, then add fine silica sand, aluminum oxide or other suitable filler. The amount added will dictate the resulting density and surface texture.

The EpoxyGuard Epoxy Floor Paint can be left as cured, or it can be top coated with a urethane to enhance the color and wear resistance.